1. CarNeuTEC ™ Environmental protection intelligent carbon reduction technology

2. High temperature plasma hazardous waste disposal technology

3. Acidified oil wastewater treatment and resource recovery technology

4. AOD refining technology of rare earth alloy steel

5. Nano photocatalyst technology

1. Red mud processing project

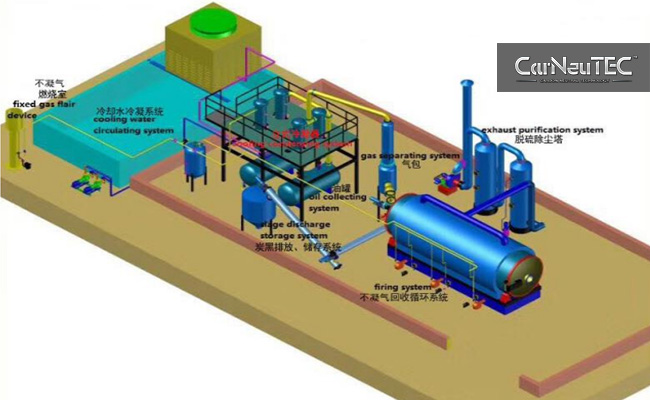

2. Waste tire project

3. Automobile disassembly, recycling and reproduction project

4. Phosphogypsum project

5. Sludge treatment project

6. Graphite electrode project

7. Scrap iron and steel project

1. Soil remediation solutions

2. Water source pollution control solution

3. Extraction of rare and trace elements from slag and its reuse

4. E-waste recycling solutions

5. Domestic and kitchen waste treatment solutions

6. Agricultural straw reuse scheme

Renewable, recyclable, environment-friendly and pollution-free, high efficiency, low energy consumption and high added value

● high resource conversion rate. The conversion rate of renewable energy generated by non-directly usable raw materials after treatment can reach more than 95%;

● strong applicability, high acceptability of raw materials that cannot be directly used;

● the operation cost is low, and there is no need to add auxiliary fuel during operation;

● high hazard free index, no dust pollution in the environment during production, ensuring a clean and harmless working environment;

● improve the conversion rate of renewable resources, effectively and stably output heat energy, and expand the field of renewable resources utilization;

● make up for the market gap. Under the guidance of the "dual control policy", the captured hot water or steam is used in power generation, heating and other industries to make up for the shortage of energy supply in the market

● with strong investment attraction effect, the exported resources will introduce beverage and food, washing, chemical, textile and other industries into the park to serve the park, drive the local employment rate and increase local taxes;

● save energy and reduce carbon emissions in the industrial park; The output of resources can replace the traditional coal-fired heating, reduce environmental pollution and reduce the operating cost of the industrial park.

Contact Us

Contact number

0411-81821250